Hello, welcome to visit the official website of Hubei Zhonghongtian Industrial Co., Ltd.

Hello, welcome to visit the official website of Hubei Zhonghongtian Industrial Co., Ltd.

PRODUCT CENTER

Provide complete sheet metal solution for customersABOUT US

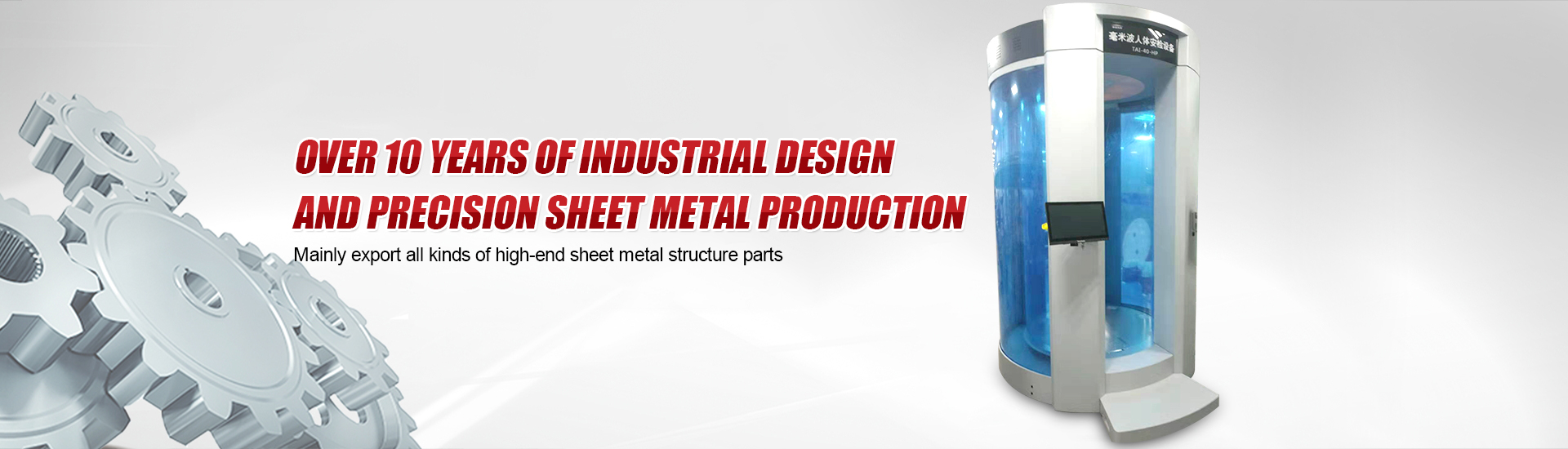

Hubei Zhonghongtian Industrial Co., Ltd. is a professional high-end man-ufacturer of sheet metal structure design and production in central China,created by a coastal elite team.Has more than 10 years experience in design and pre-cision sheet metal production, we mainly serve high-end customers bothdomestically and internationally. High end sheet metal structural compo-nents can reach international standards. The quality standard of the company has reached the international standard and has been widely recognized by customers.The companys customer base and scale are also increasing year byyear.The current company covers an area of 23000 squar......

10 years of professional sheet metal production experience, coastal elite team,The company has cutting machine, CNC punch, CNC bending machine, etc.Advanced production equipment and automatic spraying line certified by environmental protection

Founded in 2013, Hubei Zhonghongtian Industrial Co., Ltd. is a professional sheet metal processing and production base. It mainly exports various kinds of precision sheet metal, and its customers are high-end sheet metal customers. The main customers are: Germany, Nestle Switzerland, Mitsubishi Japan, etc. There are dozens of exporting countries. According to customer needs, our company can provide high-end sheet metal parts, high-end sheet metal parts can reach international standards. It has been widely praised by customers at home and abroad, and its customer group and size are increasing year by year.

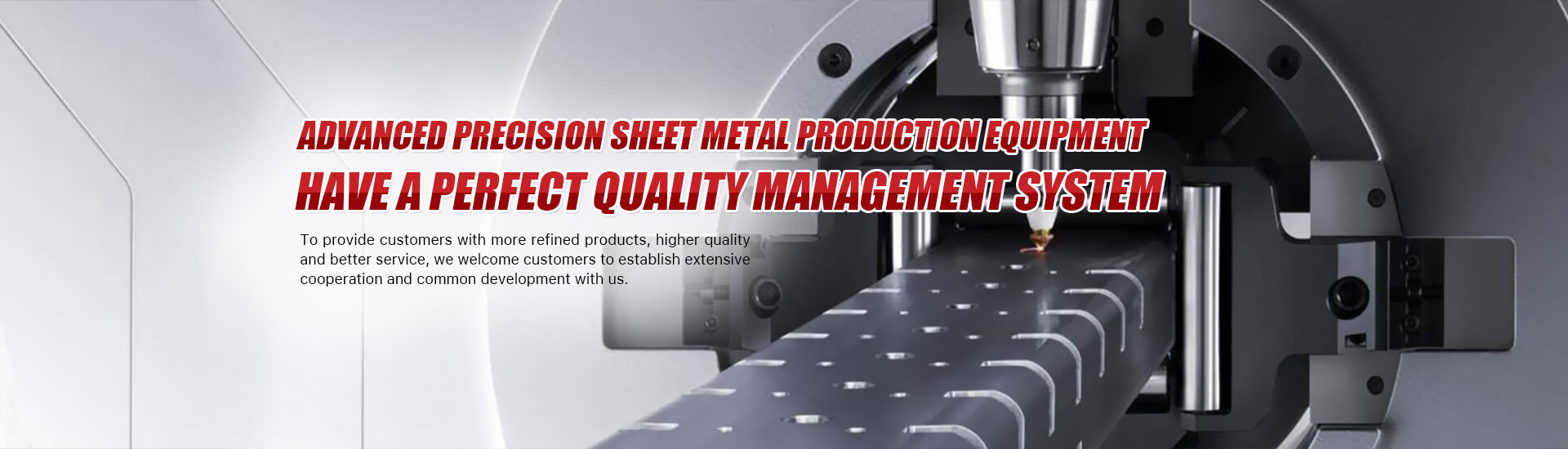

With a complete and scientific quality management system, Enterprises have passed multiple qualification certifications

The company has a group of high-quality professionals in technology, management, processing and other fields. It has about ten years'practical experience in the industry. With advanced sheet metal processing technology and professional sheet metal processing technology, the company applies SOLIDWORKS, AUTOCAD and other software-aided design to ensure the accuracy and accuracy of products.

Trustworthy enterprise

Scientific management, quality first, credit first

We are guided by the business philosophy of "quality, integrity, precision and service", the idea of excellent quality, punctual delivery and thoughtful service, and the 5S concept of on-site management to provide customers with more refined products, higher quality and better service. Welcome customers to establish extensive cooperation and common development with us.

Equipments

Advanced sheet metal processing technology and professional sheet metal processing technologyNEWS CENTER

Welcome customers to establish extensive cooperation and common development with usProcess flow of sheet metal punching

Selection of Materials The materials commonly used in sheet metal processing are cold-rolled sheet (SPCC), hot-rolled sheet (SHCC), galvanized sheet (SECC, SGCC), copper (CU), copper, beryllium copper, aluminium sheet (6061, 5052, 1010, 106The Function of Sheet Metal Bending Proce

The bending and forming of sheet metal sheet metal in bending machine are carried out. The workpiece to be formed is placed on the bending machine. The brake shoe is lifted by lifting lever, the workpiece slides to the appropriate position,Brief Introduction of Sheet Metal Technol

Sheet metal work is a kind of work developed in the early 1990s. Its predecessor is cold work. Now we are generally classified as follows: thick sheet metal: 3 mm thick sheet metal forming processing, because of thickness reasons, this kindApplication of Sheet Metal Processing

The processing steps of processing parts in sheet metal workshop are: pre-test of products, trial production of products and batch production of products. In the process of trial production, we should communicate with customers in time, getProblems to be Considered in Sheet Metal

Sheet metal is the material that most mechanical equipment must use, such as machine tools, cabinets, chassis, etc. Because of the special material properties and processing requirements of sheet metal itself, there are strict requirementslinks